While it’s possible to purchase spreader booms from retail outlets these tend to be either fixed width or made from fine wire. Where a substantial boom is required for hefty species such as cod, ling or conger the DIY route is the way to go. Norrie Southam explains how to go about producing this effective terminal tackle which fit neatly into your tackle box.

Tools Required

- Round or half-round nosed pliers

- Wire cutters

- An electric drill

- Drill bits (these should be of a size to allow two lengths of welding rod pass through but with a tight fit)

- A base wire for forming bends and coils – this should be slightly larger than the welding rod diameter but again a snug fit – alternatively a cut down hook can be used for the purpose

Materials Required

- 1.5mm stainless welding rods

- Snap link swivels (these need to have a large enough body to allow for drilling)

- Swivels

- Shrink-tube or silicon tube (a heat source will be required to contract the shrink tube).

Step 1– Drill the body of the swivel attached to the snap link – a vertical drill stand or pillar drill can make this easier and safer. As an alternative to the link swivels, a normal swivel can be used to which an oval split-ring can be attached.

Step 2– Cut the welding rod to produce two equal lengths – approximately 40cm will give a finished boom of around 60cm when expanded.

Step 3– Form a coil at one end of the cut rod by winding it round the length of forming wire, squeezing the coils tightly together as you go. A five turn coil will suffice; then cut the spare end flush with the coil.

Step 4– Bring the welding round so it lies parallel with forming rod and slide off the end. Repeat steps 2 to 4 for the second leg of the boom.

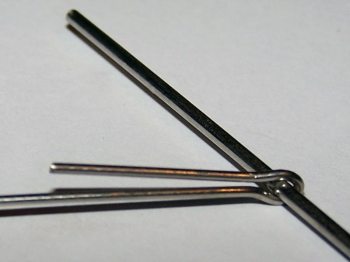

Step 5– Thread the two lengths of rod through the drill hole in the swivel and then through the open coil on the opposite ends.

Step 6– Thread the shrink tube and swivel onto one end of the boom wire. Form a loop using the wire former and thread the swivel in this loop. Squeeze the short length against the boom wire and slip the shrink tube or silicon tube over the two lengths of wire and the swivel eye; ensuring that the second eye is free to rotate. Apply heat if using shrink tube. Repeat for the other leg of the boom.

Your boom is now complete and can be stored in its collapsed state in the tackle box before extending it for use at sea.

For a general spreader boom rig see here and a “ling” spoon rigged spreader is illustrated here.